Incamake

304 ibyuma bitagira umuyonga ni ubwoko bwibikoresho byuma bidafite umwanda, kurwanya ingese birakomeye kurenza 200 byuma byuma bitagira umwanda, kurwanya ubushyuhe bwo hejuru nabyo ni byiza, birashobora kugera kuri dogere 1000-1200.304 ibyuma bitagira umwanda bifite imbaraga zo kurwanya ruswa no kurwanya ruswa hagati yintete.Kubera aside aside irwanya ubukana na positifike idafite imbaraga. umuti wa alkaline hamwe na aside nyinshi kama na organic organique.

Ibisobanuro

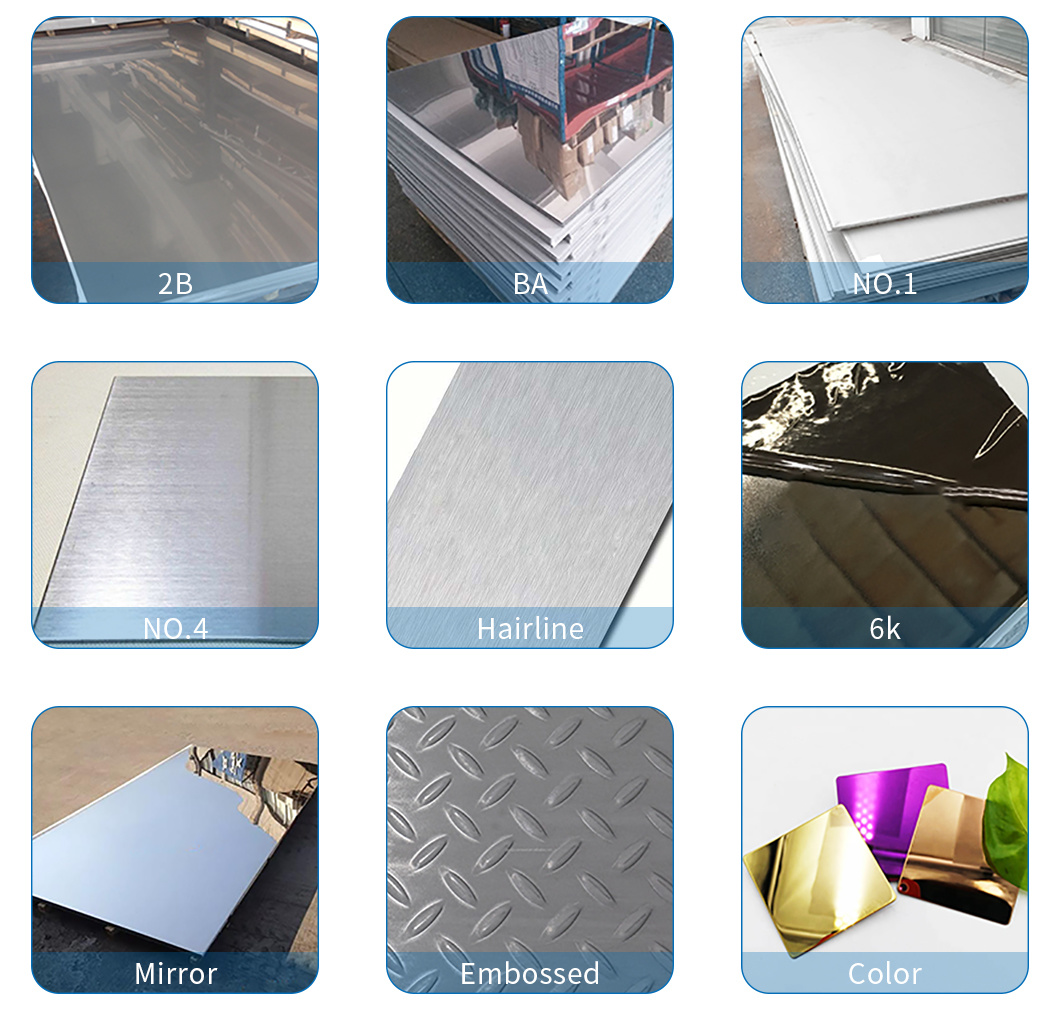

| Kurangiza | Ibisobanuro |

| 2B | Kurangiza neza, nyuma yo gukonjesha, kubwo kuvura ubushyuhe, birashobora gukoreshwa muburyo butaziguye, cyangwa nkintambwe ibanza yoza. |

| 2D | Ubuso butagaragara, buturuka kumuzingo ukonje ukurikirwa na annealing no kumanuka. Irashobora kubona urumuri rwanyuma rwanyuze mumuzingo udafite ibara. |

| BA | Bright Annealed kurangiza iboneka muguhuza ibikoresho munsi yikirere kugirango igipimo kidatanga umusaruro hejuru. |

| No.1 | Kurangiza, birangiye, bivamo kuva bishyushye kugeza kubyerekanwe. Bikurikiranye na annealing no kumanuka. |

| No.3 | Uku kurangiza gutunganijwe na No100 kugeza No.120 abrasive ivugwa muri JIS R6001. |

| No.4 | Uku kurangiza gutunganijwe na No150 kugeza No.180 abrasive ivugwa muri JIS R6001. |

| Umusatsi | Kurangiza neza, kurinzwe na firime ya PVC mbere yo gukoresha, ikoreshwa mubikoresho byo mu gikoni, |

| 8K Indorerwamo | "8" muri 8K bivuga igipimo cyibigize amavuta (304 ibyuma bitagira umwanda ahanini bivuga ibiri mubintu), "K" bivuga urwego rwo kwerekana nyuma yo gusya. 8K indorerwamo yubuso nicyiciro cyindorerwamo igaragazwa na chrome nikel alloy ibyuma. |

| Ibishushanyo | Amabati yometseho ibyuma ni ibikoresho byinshi bikoreshwa mugukora ingaruka zo gushushanya hejuru yicyuma. Nibintu byiza cyane kubikorwa byubwubatsi, gusebanya, ibimenyetso, nibindi byinshi. Nibyoroshye cyane, kandi birashobora gushirwaho kugirango bihuze ibisobanuro byuburyo butandukanye bwa porogaramu. |

| Ibara | Amabara yamabara ni titanium yubatswe ibyuma. Amabara aboneka mugukoresha inzira ya PVD. Imiterere iri hejuru ya buri rupapuro itanga ubwoko butandukanye bwo gutwikira, nka oxyde, nitride na karbide. |

Ibyingenzi Byakoreshejwe ni

1. Used yo gutunganya ubwoko bwose bwibice bisanzwe no gushiraho kashe bipfa;

2.Used nkibice bihanitse byubukanishi bwibyuma;

3. Ikoreshwa cyane muburyo bwo kuvura ubushyuhe bwo kugabanya imihangayiko mbere yo kunama.

4. Irashobora gukoreshwa nkibikoresho byubwubatsi.

7. Irashobora gukoreshwa mu nganda zimodoka.

8. Irashobora gukoreshwa mubikorwa byo murugo. Urwego rw'ingufu za kirimbuzi. Umwanya n'indege. Umwanya wa elegitoroniki n'amashanyarazi. Inganda zimashini zubuvuzi. Inganda zubaka ubwato.

Ibigize imiti yibisanzwe bikoreshwa bitagira umuyonga

| Icyiciro | C | Si | Mn | P | S | Ni | Cr | Mo | Abandi |

| 304 | .070.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0 / 10.5 | 17.5 / 19.5 | - | N≤0.10 |

| 304H | 0.04 / 0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0 / 10.5 | 18.0 / 20.0 | - | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0 / 12.0 | 17.5 / 19.5 | - | N≤0.10 |

| 304N | .080.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0 / 10.5 | 18.0 / 20.0 | - | N: 0.10 / 0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0 / 12.0 | 18.0 / 20.0 | - | N: 0.10 / 0.16 |

| 309S | .080.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0 / 15.0 | 22.0 / 24.0 | - | |

| 310S | .080.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0 / 22.0 | 24.0 / 26.0 | - | |

| 316 | .080.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0 / 14.0 | 16.0 / 18.0 | 2.00 / 3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0 / 14.0 | 16.0 / 18.0 | 2.00 / 3.00 | N≤0.10 |

| 316H | 0.04 / 0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0 / 14.0 | 16.0 / 18.0 | 2.00 / 3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0 / 14.0 | 16.0 / 18.0 | 2.00 / 3.00 | N: 0.10 / 0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0 / 15.0 | 18.0 / 20.0 | 3.0 / 4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0 / 15.0 | 18.0 / 20.0 | 3.0 / 4.0 | N: 0.10 / 0.22 |

| 321 | .080.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0 / 12.0 | 17.0 / 19.0 | - | N≤0.10Ti: 5ʷʢC + Nʣ / 0.70 |

| 347 | .080.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0 / 13.0 | 17.0 / 19.0 | - | Nb: 10ʷC / 1.00 |

| 904L | ≤0.020 | .00.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0 / 28.0 | 19.0 / 23.0 | 4.00 / 5.00 | N≤0.10Cu: 1.0 / 2.0 |

-

201 304 Ibara ry'Indorerwamo Urupapuro rw'icyuma muri S ...

-

316L 2B Yagenzuwe Urupapuro rwicyuma

-

304 Amabati yamabara yamabati

-

430 Urupapuro rudafite ibyuma

-

SUS304 Urupapuro rwumuringa

-

201 J1 J3 J5 Urupapuro rwicyuma

-

Amabati atobora

-

PVD 316 Urupapuro rwamabara

-

SUS304 BA Amabati Yicyuma Igipimo Cyiza

-

SUS316 BA 2B Amabati yamashanyarazi